Infrared Thermography Services

What is infrared thermography?

Infrared (IR) cameras see heat the same way that a standard camera sees visible light. Some interpret IR as a technology that "sees through walls". IR cameras do not see through walls, but they can observe temperature differences on the surface of the wall that result from conditions behind those walls. Note, though, that the correct conditions must be present for the camera to perceive the temperature differences. For example, time of day is crucial for performing a diagnostics on a building shell because the sun can heat the building to the point where conditions within walls will not have a sufficient temperature difference to appear to the camera, especially the cheaper cameras. A proper electrical inspection should occur when circuits are loaded. Beware of inspectors who use cameras with NETD (or resolution) above 0.07°C (7mK), as such a camera may not have the ability to sufficiently discern temperature differences.

IR Services

We offer a full array of thermal imaging services with the use of a high quality infrared camera. This technology has a myriad of uses in building diagnostics and industrial non-destructive testing. All testing is performed by a Certified Level I Thermographer, an industry standard. Here are services that we offer:

Moisture intrusion diagnosis

Leak from a washer is visible only through IR imaging (on right)

|

Water intrusion can be difficult to diagnose without removing walls. In some cases thermal imaging can track down where the leak is coming from with the minimal amount of removal of finished surfaces.

Locate air leakage and missing or deficient insulation

Warm air escaping around top of second floor wall (also deficient insulation under window) |

These items show up very well with thermal scanning and air leaks can be readily identified with the use of a blower door.

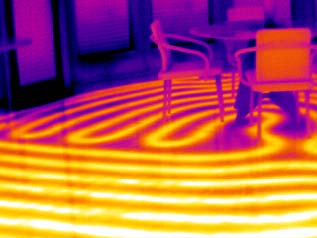

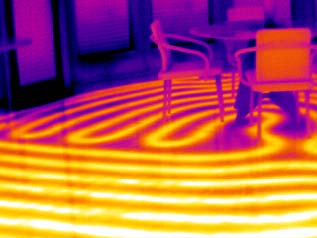

Radiant heat pipe leakage

Exact location of radiant piping is readily visible to an IR camera |

Leakage of radiant piping under a concrete slab is very difficult to locate without the use of infrared, and absolutely simple to locate in a matter of minutes with minimal floor damage using infrared.

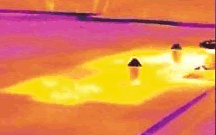

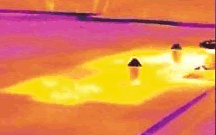

Flat roof inspections

Yellow area on flat roof shows exactly where water leakage has ruined insulation |

Repairing a flat roof is always easier than replacing it, but a proper repair should involve replacing insulation boards below the roof membrane that have been damaged by water. Water will significantly degrade insulation performance, resulting in energy losses. With an infrared scan, the exact areas of damage can be outlined with spray paint for replacement. This is a great maintenance service to perform yearly on a flat roof, as sometimes leakage can occur for a long time before it is discovered.

Note that the following conditions must exist for a successful flat roof inspection:

- You must have some awareness of the nature of the roof assembly, i.e., what's beneath the membrane surface? Inuslation boards? Wood roof deck? Metal roof deck?

- The roof surface to be surveyed must be completely dry and exposed at sunrise.

- No ice, snow, or standing water can be present

- No items, including construction materials, debris, leaves, decking, etc. can be present

- Weather for the day must be mostly sunny

- No rain, sleet, or snow

- Daytime high temperatures should be at least 40°F

- Wind speed must be no greater than 15 mph between sunrise and evening when the survey is conducted

The idea is to let sunlight warm the roof, which will load the water inside the roof with heat. The survey is conducted shortly after the sun sets, when outside temperatures are a little cooler than daytime. At this time, the roof surface will cool, but the water within the roof assembly will still be warm, giving its heat up to the roof surface. The wet areas will then be visible to the infrared camera and can be documented.

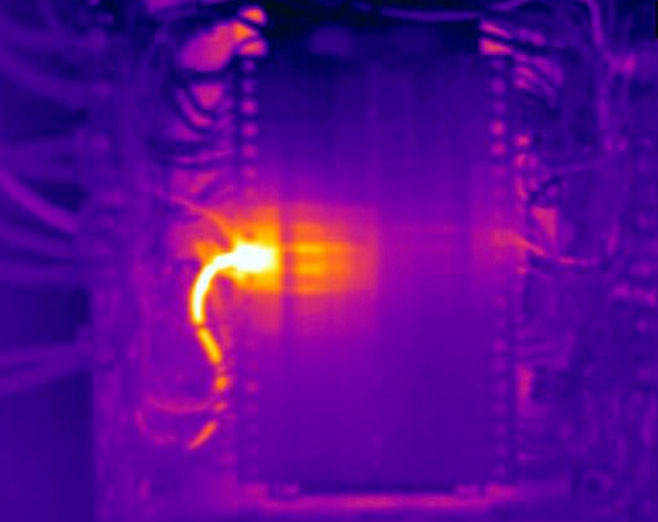

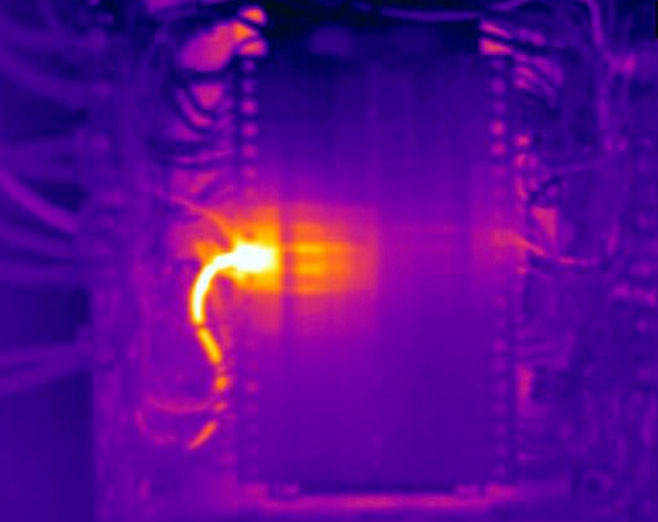

Electrical inspections

The lit up circuit is overheating and a fire may start soon

|

Electrical connections and circuits can be overheating without any visible evidence. This overheating can be easily identified with a thermal scan. In houses and buildings, electrical fires can be avoided and preventive maintenance can occur without component failure. Electrical inspections in industrial settings can help avoid potential costly equipment failures, problems with transformers, and other electrical connections that are overheating.

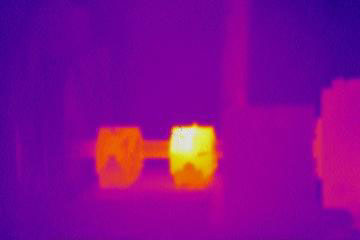

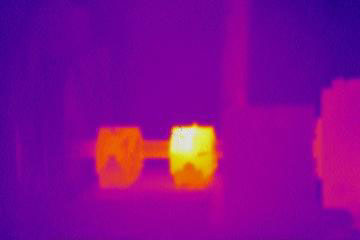

Motor analysis

The bearing is much hotter than the shaft and motor body. It will seize soon |

Motors can overheat at shaft bearings or inside, resulting in failure which can result in costly production stoppage. IR can diagnose potential overheating scenarios before failure occurs.